Flashing a light on our story

Al Gioshy Steel Group, founded in 1985, is a trusted supplier of construction materials in Egypt. They expanded by importing raw materials and established a successful building materials business in Qatar in 2004.

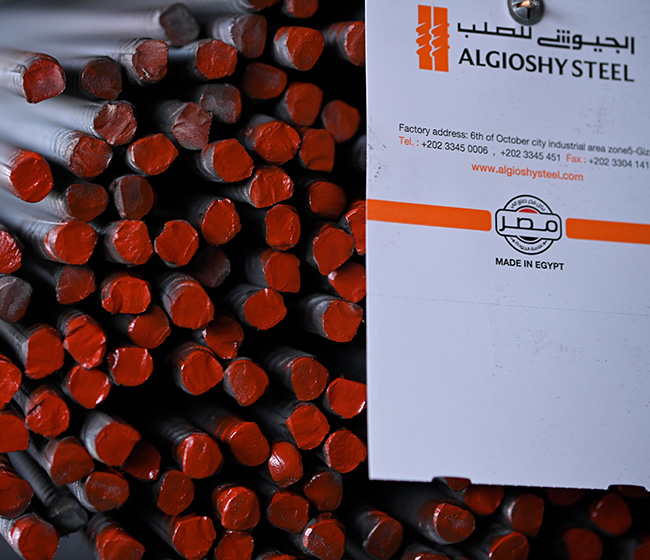

Recognizing the growing steel demand, they built the AlGioshy Steel Rolling Mill in 2011. In 2015, AlGioshy Steel Production commenced operations to increase production capacity. With a commitment to quality, they contribute to Egypt's economy and prioritize customer satisfaction. Their strategic location near Cairo and Giza ensures proximity to consumer centers.

Al Gioshy Steel Group remains dedicated to staying ahead of the competition and achieving continuous growth in the industry.

Know More!